LED main production process:

Material: LED stent; LED chips; LED solid crystal plastic; welding wire; LED packaging glue; LED Phosphor; mainly over several materials.

Equipment: Automatic Bonder; plasma cleaning machine; automatic wire bonders; automatic dispenser; glue mixer; oven; Slitter; automatic sorting machine; automatic packaging machines;

Production environment: LED packaging factory generally require one hundred thousand dust; may require greater protection in the dispensing room, hope is ten thousand dust; backend test sorting requirements lower, one million dust can be. But the whole need to be a good ESD protection, because the LED chip afraid electrostatic breakdown.

The first step: LED stand test. The main test items: Dimensions, plating thickness, if there is oxidation. Recommend the use of tools: the second element meter, thickness tester, metallurgical microscope.

Step two: LED bracket baking. The LED holder using the device and baked primarily to the stent during injection of residual water vapor removal.

The third step: LED bracket plasma cleaning. Plasma cleaning device is formed mainly in the inside of the arc from hydrogen and oxygen, the LED support surface residual organics removal, improve solid crystal adhesion.

Step Four: solid crystal. The LED chip Bonder automatic pick with LED solid crystal glued on the LED holder.

Step five: baking. The solid crystal glue dry baking, make LED chips and LED bracket form a good bond. After baking, etc., to be solid crystal thrust test equipment is very expensive, oh, push pull test.

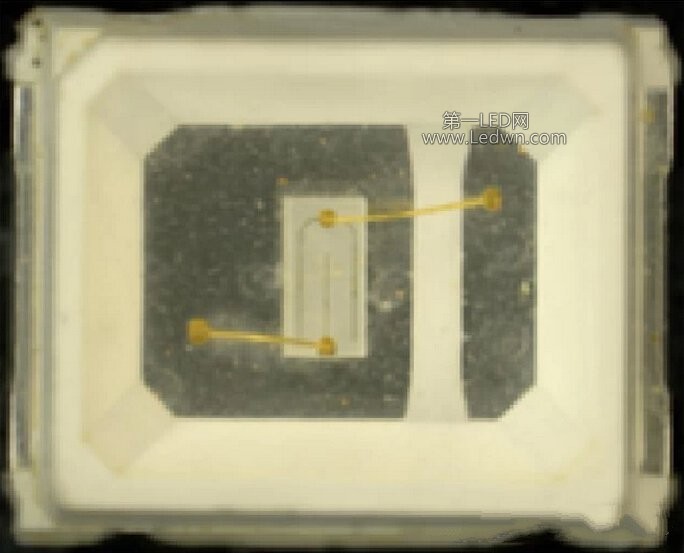

Step Six: wire bonders. The conductive regions on the pads of the LED chip and the LED on the bracket using a metal wire for welding. Welding is divided into categories: gold spherical welding, wedge welding wire used are: gold, aluminum alloy wire, copper wire, LED lamp beads are mainly used gold, and copper alloy wire. After welding is completed to measure the size of the solder joints, welding tension. This is a very critical step, most of the LED lights are dead because of problems caused by welding.

Step Seven: sealant. Cup-shaped area formed by the use of LED bracket LED packaging glue to fill, if the production of white LED lamp beads, then you need to add the right amount of glue inside phosphor. This step is a step to produce white light, and also decided to color temperature, CRI, and color of each step, the production of white light beads companies will have a dedicated person deployment of phosphor.

Step Eight: baking. The LED package glue cured by oven.

Step 9: slitting. The LED support from a lot of connections with the sheet, cut into small independent LED lamp unit.

Step 10: sorting. The various small lamp beads cut by setting various parameters: voltage, color temperature, flux and other sorting.

Step Eleven: The lamp beads with the same parameters were taping.

The main steps to end it, the above is a major producer of SMD LED step. Currently, like high power cree, OSRAM and other kind of lensed, processes and equipment in the phosphor coating and sealant link different aspects of the use, or roughly the same process.